290T Twill Nylon Oxford Fabric – Your Go-To Material for Outdoor Adventure Gear

When it comes to crafting outdoor gear that can withstand the toughest conditions, material choice is everything. Enter 290T Twill Nylon Oxford Fabric — a revolutionary textile designed to meet the demands of modern adventurers. Whether you're stitching a backpack for global travel, building a weatherproof tent, or crafting a picnic mat that won’t let a drizzle ruin your day, this fabric stands ready to perform.

The Fabric That Never Backs Down: Meet 290T Twill Nylon Oxford

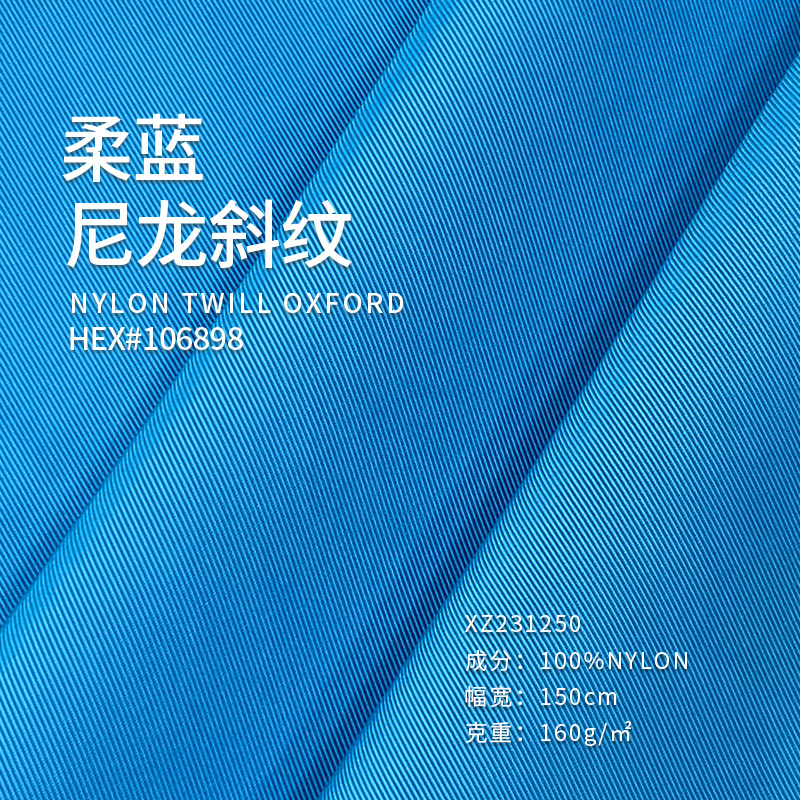

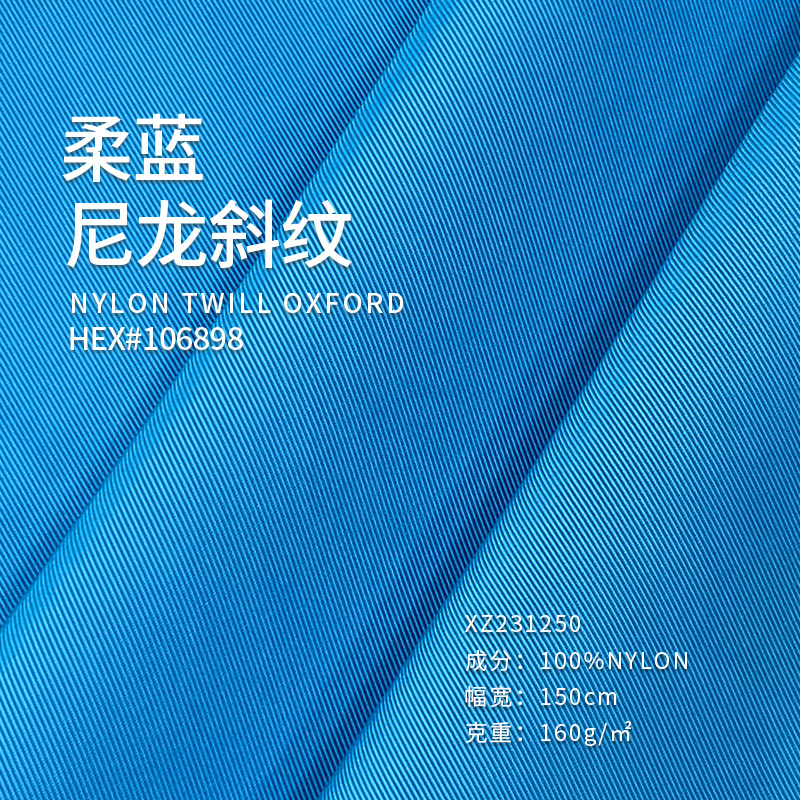

The story behind 290T Twill Nylon Oxford begins with a need for balance — between strength and weight, durability and flexibility, performance and cost. The “290T” refers to the thread count per square inch, indicating a tightly woven structure that enhances both resilience and water resistance. This fabric combines the diagonal rib pattern of twill weaving with the textured, basket-like appearance of Oxford fabric, creating a material that’s not only tough but also visually appealing.

This unique weave offers a dual advantage: it’s strong enough to resist abrasion and tearing, yet soft enough to be used in a variety of applications, from rugged camping gear to sleek urban backpacks.

Built to Brave the Elements: Weather-Ready Performance

One of the standout features of 290T Twill Nylon Oxford is its impressive weather resistance. A high-quality waterproof coating applied during manufacturing ensures that moisture stays on the surface without seeping through. This makes it ideal for use in environments where sudden downpours or humid conditions are common.

Its anti-tear and abrasion-resistant properties are particularly valuable for outdoor enthusiasts. Whether you're trekking through rocky terrain or setting up camp in the wind, this fabric is engineered to hold its ground. And despite its strength, it remains incredibly lightweight — a critical factor for travelers and adventurers who value portability without sacrificing durability.

From Backpacks to Basecamps: Real-World Applications

The versatility of 290T Twill Nylon Oxford makes it a go-to material across a wide range of products. For backpacks, it provides a lightweight yet sturdy shell that can handle everything from daily commutes to multi-day hiking trips. Its resistance to water and wear ensures that your gear stays protected, no matter the environment.

In tents, this fabric forms a reliable outer layer that shields you from wind and rain while maintaining breathability. It’s also a top choice for picnic mats — offering comfort underfoot and easy cleaning after a muddy outing. Outdoor storage bags, duffels, and even waterproof accessories like phone cases and laptop sleeves benefit from its robust nature and clean finish.

Why It Outshines the Competition: A Material Comparison

When compared to other nylon fabrics like 210D or 420D, 290T Twill Nylon Oxford strikes a unique balance. While 210D is lighter, it often lacks the durability required for heavy use. On the other hand, 420D offers strength but can be bulky and less flexible. 290T Twill Nylon Oxford sits in the sweet spot — offering the perfect blend of weight, strength, and texture.

Compared to polyester, this nylon variant typically provides better abrasion resistance and a more natural drape. It also holds up better under UV exposure and repeated folding, making it a more reliable option for long-term outdoor use.

Designers’ Dream: How to Work with 290T Twill Nylon Oxford

For DIY enthusiasts and professional designers alike, 290T Twill Nylon Oxford is a joy to work with. Its consistent weave allows for clean, precise cuts, and it sews smoothly with standard industrial or home sewing machines. The fabric accepts dyes and prints exceptionally well, making it a versatile canvas for custom designs and branding.

Whether you're creating a custom camping mat or launching a new line of travel bags, this fabric offers the flexibility to bring your vision to life without compromising on quality or performance.

Sustainability Meets Strength: Eco-Friendly Potential

As the outdoor industry moves toward more sustainable practices, 290T Twill Nylon Oxford shows promise in eco-friendly applications. Its durability means products last longer, reducing the frequency of replacements and minimizing waste. Some manufacturers are exploring ways to incorporate recycled nylon into the weave, paving the way for greener outdoor gear without sacrificing strength or water resistance.

Additionally, its lightweight nature contributes to lower shipping emissions — another small but meaningful step toward environmental responsibility.

Customer Stories: How People Are Using It Today

Across the globe, outdoor lovers and makers are discovering the benefits of 290T Twill Nylon Oxford. From custom-built camping mats to modular backpack systems, users praise its durability and ease of use. One customer even crafted a waterproof pet bed cover that withstands muddy paws and rainy walks.

Designers in the home goods sector have begun using it for coasters and waterproof table linens, proving that its utility isn’t limited to the great outdoors. Community forums and maker groups frequently highlight this fabric as a favorite for both practicality and aesthetic appeal.

What’s Next for 290T Twill Nylon Oxford? Future-Proofing Your Projects

As material science continues to evolve, 290T Twill Nylon Oxford is poised for even broader applications. Emerging uses include protective covers for drones, lightweight outdoor furniture, and even smart textiles that integrate with wearable tech. Its adaptability makes it a prime candidate for innovation in the outdoor and tech-integrated fabric space.

Whether you're designing the next generation of camping gear or crafting a custom bag for your brand, 290T Twill Nylon Oxford offers the strength, versatility, and future-ready qualities you need to stand out.

Ready to elevate your next project with a fabric that combines performance, style, and resilience? 290T Twill Nylon Oxford is more than just a material — it's a foundation for adventure, creativity, and lasting quality.