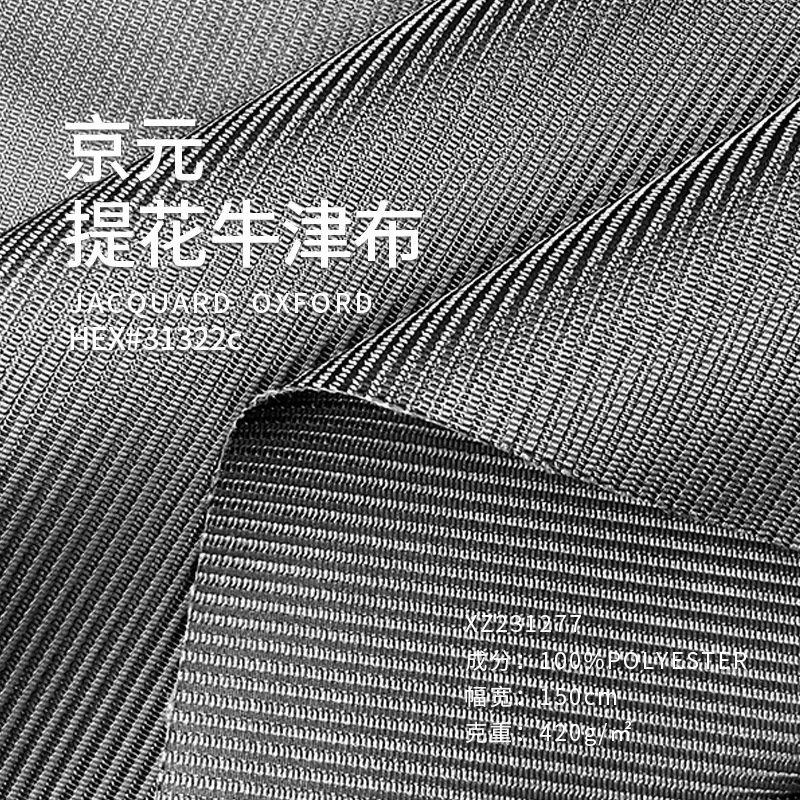

Understanding 420D Coarse Vertical Stripe Oxford Cloth

420D coarse vertical stripe Oxford cloth is a durable and versatile fabric widely used in various industries. The '420D' indicates the denier count, reflecting its strength and weight. Its coarse texture makes it robust enough to withstand wear and tear.

The vertical stripe pattern not only adds a visual element but also influences how the fabric reacts during the printing process. These stripes can serve as alignment guides ensuring precise and consistent prints.

Applications and Uses

This textile is commonly found in products like bags, tents, and pet mats, thanks to its rugged nature. Many prefer 420D Oxford cloth for outdoor gear due to its water-resistant properties provided by coatings or composite surfaces. It offers durability, making it an ideal choice across various sectors.

Preparing for Printing

Selecting the Right Printing Method

Choosing between screen printing and digital printing depends on specific project needs. Screen printing excels in producing vibrant colors on coarse fabrics, while digital printing allows for detailed designs and faster production times. Both have unique advantages that cater to different requirements.

Pre-Treatment of Fabric

Prepping the fabric involves cleaning the surface to remove any dust or oils that may interfere with ink adherence. Using primers or special coatings ensures the ink penetrates well into the fibers, reducing the chances of fading and enhancing print durability.

Tips for Effective Printing

Choosing the Right Ink

Synthetic and UV-curable inks are excellent choices for 420D Oxford cloth. These inks resist environmental stressors such as sunlight and moisture, preserving the vibrancy of the print over time. Always consider eco-friendly options where possible to minimize environmental impact.

Adjusting Print Settings

For optimal results, adjust temperature and pressure settings according to the fabric’s characteristics. High temperatures ensure better ink bonding, whereas appropriate pressure avoids damaging the fabric or causing misalignment. Proper adjustment helps achieve vibrant colors and sharp details.

Techniques for Best Results

Layering and Overprinting

Multi-layer prints enhance depth and richness. When applying additional layers, make sure each previous layer is completely dry. Control ink spread by using precise overprinting techniques, which prevent bleeding and maintain clarity.

Handling the Fabric During Printing

Securing the fabric tightly prevents movement that could cause smudging or misaligned prints. Pay attention to maintaining stripe alignment, especially when dealing with patterned fabrics. This ensures consistency throughout the printed material.

Post-Printing Considerations

Drying and Curing

Proper drying and curing are essential to set the ink firmly. Follow recommended drying times and methods, whether air drying or heat setting, to enhance durability. Well-cured prints withstand extensive use and washing cycles without deteriorating.

Quality Control

Inspect finished products meticulously for print consistency and errors. Common issues include misalignment and color fading. Address these immediately to maintain high standards and customer satisfaction. Consistent quality checks lead to reliable output.

Enhancing Durability and Appearance

Protective Coatings and Finishes

Applying protective coatings enhances the lifespan of printed fabrics. Options range from water-resistant sprays to UV-protective finishes. These coatings might slightly alter the fabric's feel, adding flexibility and softness based on the applied finish.

Maintenance and Care Tips

Follow specific cleaning guidelines to preserve prints. Use mild detergents and avoid harsh chemicals. Hand washing is preferable though machine washing on gentle settings works as well. Store printed fabrics away from direct sunlight to prevent premature fading.

Troubleshooting Common Problems

Ink Smudging or Bleeding

Common causes include improper pre-treatment or incorrect ink types. To prevent this, double-check compatibility and ensure thorough pre-print preparations. Avoid excessive ink application that leads to undesired spreading.

Print Misalignment

Consistency is key. Secure the fabric adequately before and during printing. Utilize tools such as clamps or adhesive-backed substrates to hold the fabric steady, promoting uniformity across multiple prints.

Color Fading

Ensure colorfastness by selecting compatible inks and following prescribed curing processes. Protective topcoats add endurance against fading caused by regular usage and exposure to elements.

Case Studies and Examples

Real-Life Applications

Success stories abound in various industries. For instance, outdoor equipment manufacturers leverage 420D Oxford cloth for waterproofs and adventure gear, resulting in robust and visually appealing products. Lessons from such cases highlight the importance of tailored approaches to printing techniques depending on end-use scenarios.

Visual Gallery

Explore a curated gallery showcasing diverse uses of printed 420D vertical stripe Oxford cloth. From sleek backpacks to durable pet mats, find inspiration for your next project through real-world examples demonstrating effective utilization of this versatile material.

Additional Resources

Recommended Tools and Supplies

A successful printing setup includes quality printers, suitable inks, and professional-grade pre-treatment materials. Reliable suppliers often provide bundled kits catering specifically to coarse-texture textiles like 420D Oxford cloth.

Further Reading and Tutorials

Dive deeper into specialized topics with detailed guides and video tutorials available online. Join communities and forums focused on textile printing to stay updated with trends, tips, and collective knowledge sharing. Continuous learning equates to building expertise over time.