When it comes to durable and versatile materials, few can rival the reliability of 420D Oxford cloth. Known for its robustness and adaptability, this fabric is widely used across various industries including outdoor gear, promotional products, and more. In this guide, we'll delve into the specifics of waterproof printing on 420D Oxford cloth, ensuring you get vibrant, long-lasting results.

Understanding 420D Oxford Cloth

Overview of 420D Oxford Cloth Properties

420D Oxford cloth is a type of woven polyester fabric that features a polyurethane coating, providing enhanced durability and water resistance. The "420D" stands for the denier count, indicating the thread thickness — in this case, 420 denier, which strikes a balance between ruggedness and flexibility.

This material is commonly employed in making bags, tents, pet mats, and other demanding applications due to its strength and resilience against wear and tear. Its advantages include water-repellency, ease of cleaning, and durability, making it a favored choice over many alternatives like Nylon or Cotton.

Comparison with Other Materials

Compared to fabrics such as Nylon, 600D Polyester, or basic canvas, 420D Oxford cloth offers unique benefits particularly suited for waterproof applications. While Nylon offers strong tensile strength, 420D Oxford provides superior water resistance thanks to its PU coating. Similarly, compared to 600D Polyester, 420D’s lighter weight makes it easier to handle while still maintaining durability, especially suitable for activities requiring waterproof properties.

Techniques for Waterproof Printing

Pre-treatment of 420D Oxford Cloth

Before diving into the actual printing process, it's crucial to prepare your 420D Oxford cloth properly. Start by thoroughly cleaning the fabric to remove any dust, dirt, or oils that could prevent the ink from adhering smoothly. You'll need some mild detergent, clean water, and a soft brush for scrubbing. After washing, let the fabric dry completely.

Gather recommended tools like heat press machines, high-quality waterproof inks, stencils, and squeegees depending on your chosen method. These will ensure you're set up for success right from the beginning.

Waterproof Printing Methods

There are several methods to achieve high-quality prints on 420D Oxford cloth:

- Direct-to-Garment (DTG) printing: This technique allows for detailed designs and vivid colors directly printed onto the fabric using specialized DTG printers designed for challenging surfaces.

- Heat transfer printing: Ideal for intricate designs, this involves transferring a design onto the fabric using heat and pressure to ensure the print adheres securely.

- Screen printing: A traditional method perfect for bold, simple designs. It utilizes stenciling screens to directly apply each color layer to the cloth, resulting in highly durable prints.

Step-by-Step Waterproof Printing Process

Here’s a high-level overview of how to print on 420D Oxford cloth:

- Ensure the fabric is pre-treated and dried completely.

- Choose the appropriate printing method based on your design needs and available equipment.

- For DTG, load the fabric onto the printer platform, select your design, and start printing.

- For heat transfer, print your design on transfer paper, position it correctly on the cloth, and use a heat press machine to adhere the design.

- For screen printing, create your stencil, align it on the fabric, and manually press ink through the screen onto the cloth.

- Allow sufficient drying/curing time as per ink manufacturer's recommendations.

Pro tip: Conduct test prints on small samples to fine-tune settings before proceeding with larger quantities. This ensures optimal alignment and ink adherence.

Benefits of Waterproof Printing on 420D Oxford Cloth

Enhanced Durability

One of the most significant benefits of printing on 420D Oxford cloth is its impressive durability. The combination of robust fabric and waterproof printing techniques means the finished product can withstand harsh weather conditions without fading or peeling.

Versatility

Waterproof printed 420D Oxford cloth finds applications in a plethora of areas. From creating stylish yet functional outdoor gear like tents and backpacks to producing eye-catching promotional banners and decorative items, this material's versatility is unmatched.

Aesthetic Appeal

The rich texture and ability to hold vibrant colors make 420D Oxford cloth an excellent choice for aesthetic appeal. Customization options are nearly endless, catering to various industries' needs, enhancing brand visibility, and appealing to diverse consumer preferences.

Maintenance and Care

Cleaning Techniques

Maintaining your printed 420D Oxford cloth involves gentle cleaning to preserve its water-resistant properties. Use mild detergents and cold water, avoiding harsh chemicals and abrasive brushes. Air-drying is preferable to maintain fabric integrity.

Repair and Longevity

To address minor wear and tear, consider using fabric adhesives or patches specifically designed for coated textiles. Proper storage away from direct sunlight and sharp objects also extends the life and vibrancy of your printed materials.

Environmental Impact and Considerations

Eco-Friendly Printing Practices

Sustainable practices enhance eco-friendliness in waterproof printing processes. Opt for non-toxic, water-based inks and minimize waste by precise planning and efficient production techniques. Reducing energy consumption during manufacturing also contributes to overall sustainability.

Recycling and Disposal

Proper disposal is essential in extending environmental responsibility. Research recycling programs tailored towards synthetic fabrics like 420D Oxford cloth. Participating in these initiatives helps divert materials from landfills and promotes circularity within the textile industry.

Case Studies and Examples

Real-World Applications

Diverse industries have leveraged waterproof printing on 420D Oxford cloth with great success. Outdoor brands report improved sales and customer satisfaction with long-lasting, vividly printed products. Promotional events benefit heavily from striking banners and signage crafted from this durable material.

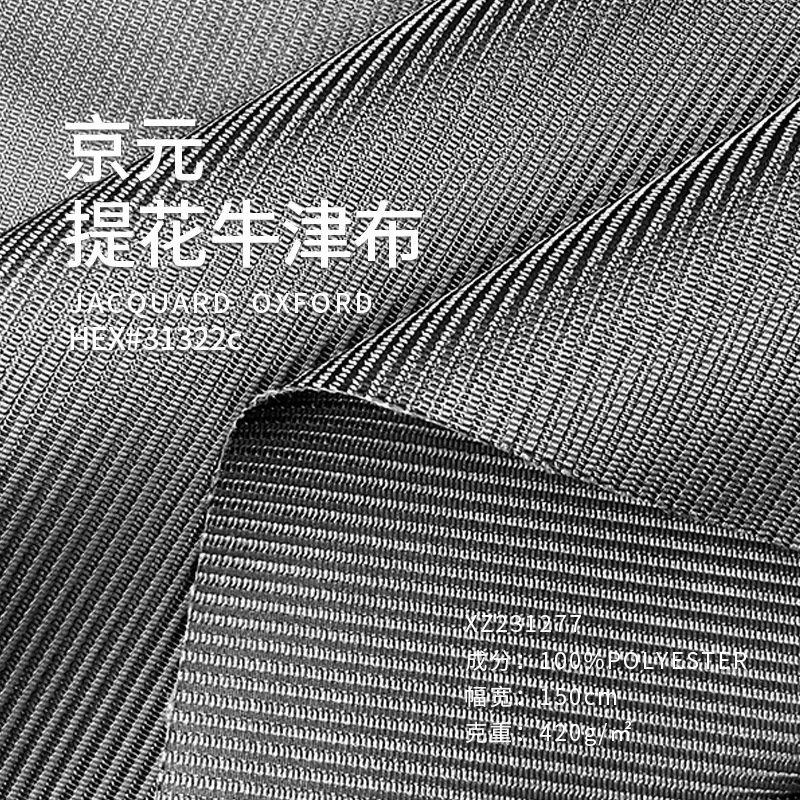

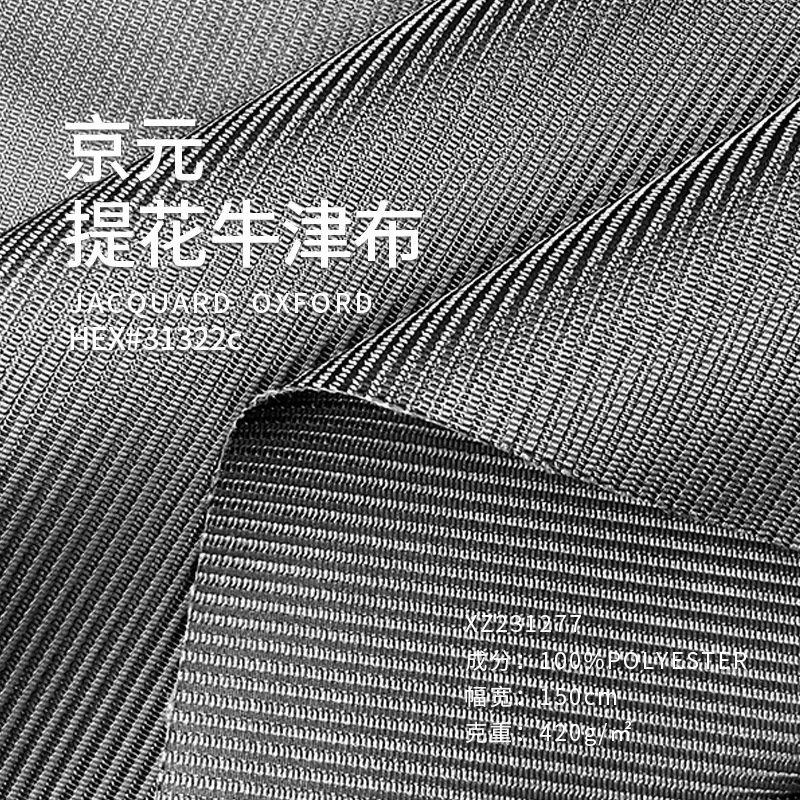

Visual Gallery

The following images showcase real-world examples of stunning prints achieved on 420D Oxford cloth:

Future Trends in Waterproof Printing

Innovations and Technological Advancements

Emerging technologies promise even greater precision and efficiency in waterproof printing. Innovations like nanotechnology-based coatings and digital printing advances are on the horizon, enabling more resilient and intricate designs on fabrics like 420D Oxford cloth.

Market Trends and Consumer Preferences

Consumer demand increasingly leans towards sustainable, high-performance textile solutions. Industries are expected to witness steady growth in the adoption of waterproof printed materials, driven by advancements and evolving market preferences focused on quality and sustainability.