Premium 290T Twill Nylon Oxford Fabric: Waterproof & Versatile Material for Bags, Tents & Picnic Mats

When adventure calls, the last thing you want is compromised gear. Behind every reliable backpack, weatherproof tent, or easy-clean picnic mat lies an unsung hero—high-performance fabric. Enter the 290T Twill Nylon Oxford: a cutting-edge textile redefining durability, versatility, and protection across outdoor and lifestyle products.

Where Outdoor Meets Innovation: How One Fabric Redefines Gear Boundaries

From military-grade duffels to weekend picnic essentials, modern consumers demand more than just function—they expect resilience without weight, style without compromise. The evolution from heavy canvas to advanced synthetic textiles has been transformative. Today’s top outdoor brands are turning to engineered fabrics like 290T nylon oxford not just for their toughness, but for their intelligent balance of strength, water resistance, and portability.

This shift reflects a broader trend: performance-driven design. As urban explorers embrace “glamping” and micro-adventures, the need for lightweight yet rugged materials has surged. The 290T Twill Nylon Oxford stands at the intersection of tradition and technology—rooted in proven weaving techniques, yet enhanced with modern coatings and precision engineering.

Decoding the DNA of 290T: More Than Just Thickness

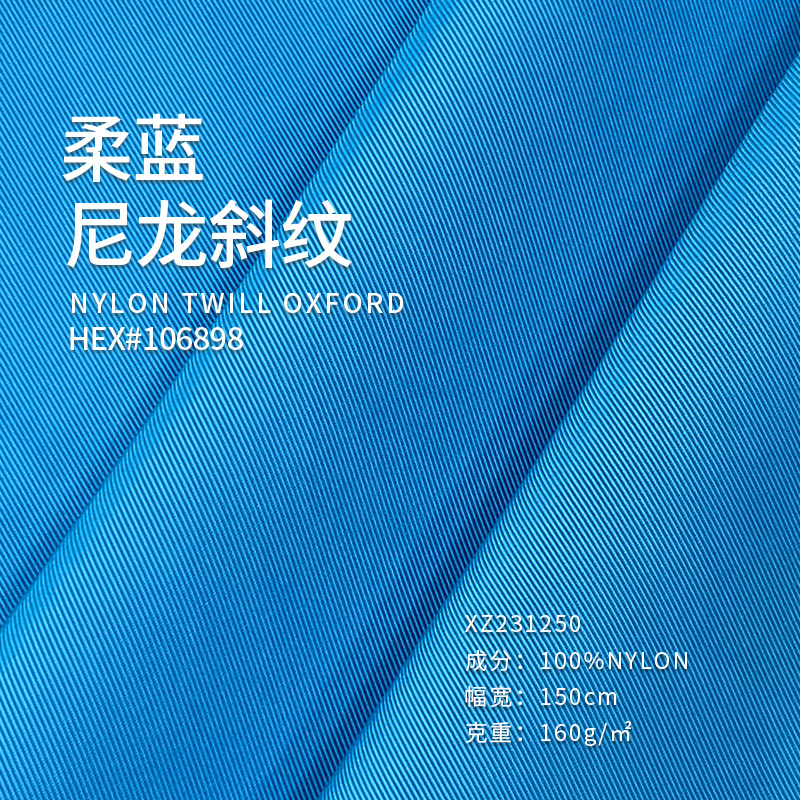

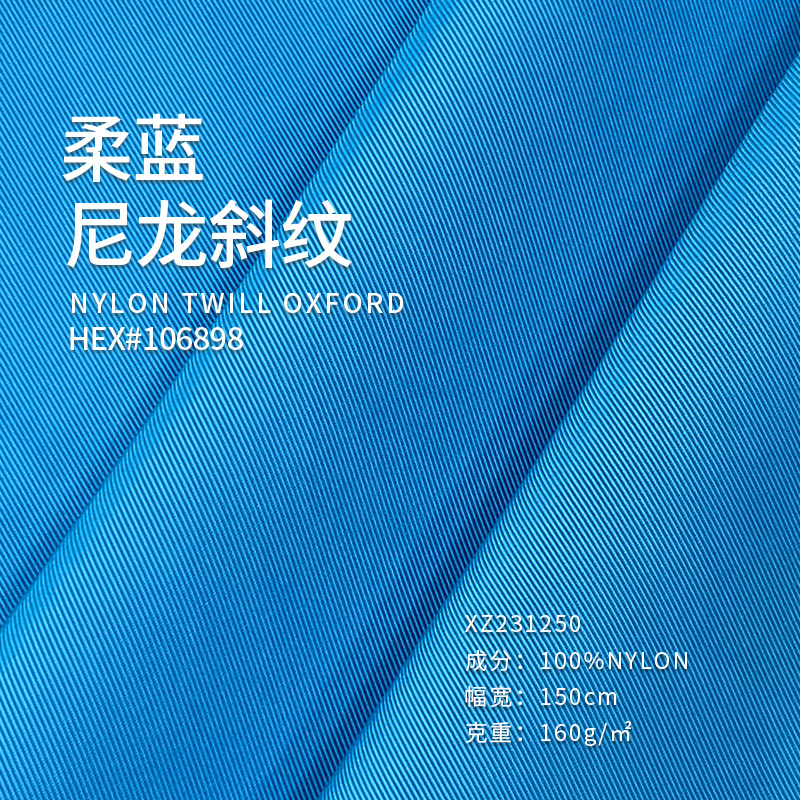

The “290T” designation isn’t arbitrary—it refers to thread count per inch, indicating a tightly woven structure that resists abrasion and tearing. But what truly sets this fabric apart is its twill weave. Unlike flat weaves, twill creates diagonal rib patterns that distribute stress more evenly, significantly boosting tear resistance. This structural advantage makes it ideal for high-stress zones in backpacks or folding mechanisms in picnic mats.

Combining nylon’s inherent elasticity and strength with the reinforced cross-hatch pattern of Oxford weaving results in a material that’s both featherlight and fortress-strong. It bends without breaking, folds without fraying—a rare harmony of flexibility and fortitude.

The Science of Staying Dry: Waterproof Performance That Holds Up

Rain doesn’t discriminate—and neither should your gear. Thanks to a high-quality PU (polyurethane) or PVC coating applied during manufacturing, 290T Twill Nylon Oxford achieves exceptional waterproofing. These coatings seal the weave, creating a barrier that prevents moisture penetration while maintaining breathability where needed.

In real-world testing, tents made with this fabric show no leakage at seams—even under simulated downpours. Surface tension plays a key role: water beads up and rolls off due to the fabric’s low surface energy, a phenomenon known as the lotus effect. This self-shedding capability keeps surfaces dry longer and reduces drying time after exposure.

Beyond the Wild: From Tactical Packs to Urban Picnics

Leading outdoor brands have integrated 290T nylon oxford into bestselling backpack lines, citing its ability to endure trail abuse while remaining packable. Its popularity extends beyond hiking—designers now use it for foldable picnic mats that resist mold, repel dirt, and clean with a quick wipe.

Diy enthusiasts also swear by it. One maker recently transformed a worn suitcase using this fabric, adding waterproof lining and reinforced corners. The result? A vintage look with modern resilience. Whether restoring old gear or prototyping new concepts, creatives appreciate its ease of sewing and compatibility with heat-sealing tools.

Durability Meets Responsibility: Rethinking Longevity and Sustainability

True value isn’t measured in days, but in years. UV resistance tests show minimal degradation after prolonged sun exposure, meaning gear lasts longer with less fading or embrittlement. Abrasion trials confirm superior wear performance compared to standard polyesters or cotton canvas.

And when damage does occur, repairability matters. Minor scratches or punctures can often be sealed with heat-activated patches or iron-on mends—extending product life and reducing waste. As sustainability becomes central to design, manufacturers are exploring bio-based nylons and recyclable coatings to reduce environmental impact without sacrificing performance.

Why Manufacturers Keep Coming Back: The OEM Favorite

For producers, consistency and cost-efficiency are paramount. 290T Twill Nylon Oxford delivers on both fronts. Its high strength-to-weight ratio means less material is needed per unit, lowering shipping costs and improving margins. Dye uptake is uniform, supporting rich color customization and vibrant sublimation printing.

During mass production, the fabric feeds smoothly through automated cut-and-sew lines, minimizing snags and misalignments. Batch-to-batch stability ensures fewer defects and lower scrap rates—critical for meeting large-volume orders on time and within budget.

The Future of Fabric: Where Innovation Takes Thread Next

Tomorrow’s textiles won’t just protect—they’ll interact. Research labs are experimenting with self-cleaning coatings that break down organic stains under sunlight, and integrating conductive fibers into nylon weaves for smart gear applications. Imagine a backpack that charges your phone or a tent that monitors internal humidity.

As modular, multi-use gear gains traction, 290T fabric could become the foundation for interchangeable outdoor systems—lightweight shells that adapt to changing needs. With advances in recycled and bio-derived nylon, this workhorse material may soon become a leader in eco-innovation too.

Is This the Right Fabric for Your Project?

Ask yourself: Does your product face heavy use or wet environments? Do you need a strong, lightweight base that supports printing or lamination? Can it benefit from repair-friendly, long-lasting construction? If so, 290T Twill Nylon Oxford deserves serious consideration.

Compared to alternatives like polyester taffeta, cotton duck canvas, or TPU-laminated textiles, it offers a compelling middle ground—more durable than most synthetics, lighter than traditional fabrics, and far more adaptable than rigid composites. When you request samples, pay attention not just to specs, but to hand feel, drape, and seam integrity. Real-world performance begins with tactile truth.

The 290T Twill Nylon Oxford isn’t just another fabric. It’s a benchmark for what modern performance textiles should be: tough, smart, and ready for anything. Whether you're building the next great outdoor brand or upgrading an existing line, this material might just be the foundation you’ve been searching for.